Burs come in all shapes and sizes - which bur type is determined by the operation that has to be performed. But how often can the bur be used or reused and why is using cheap burs way more expensive than using high-quality burs?

Generally speaking only burs with a valid CE, manufactured to the current ISO-3823 standard should be used. Why you may ask? Simply because the entire dental industry (as many others) is based on a system and to ensure one component fits another the components need to comply with these standards. If these standards are not met it can result in compatibility issues or even the risk of health issues for the practitioner and patient.

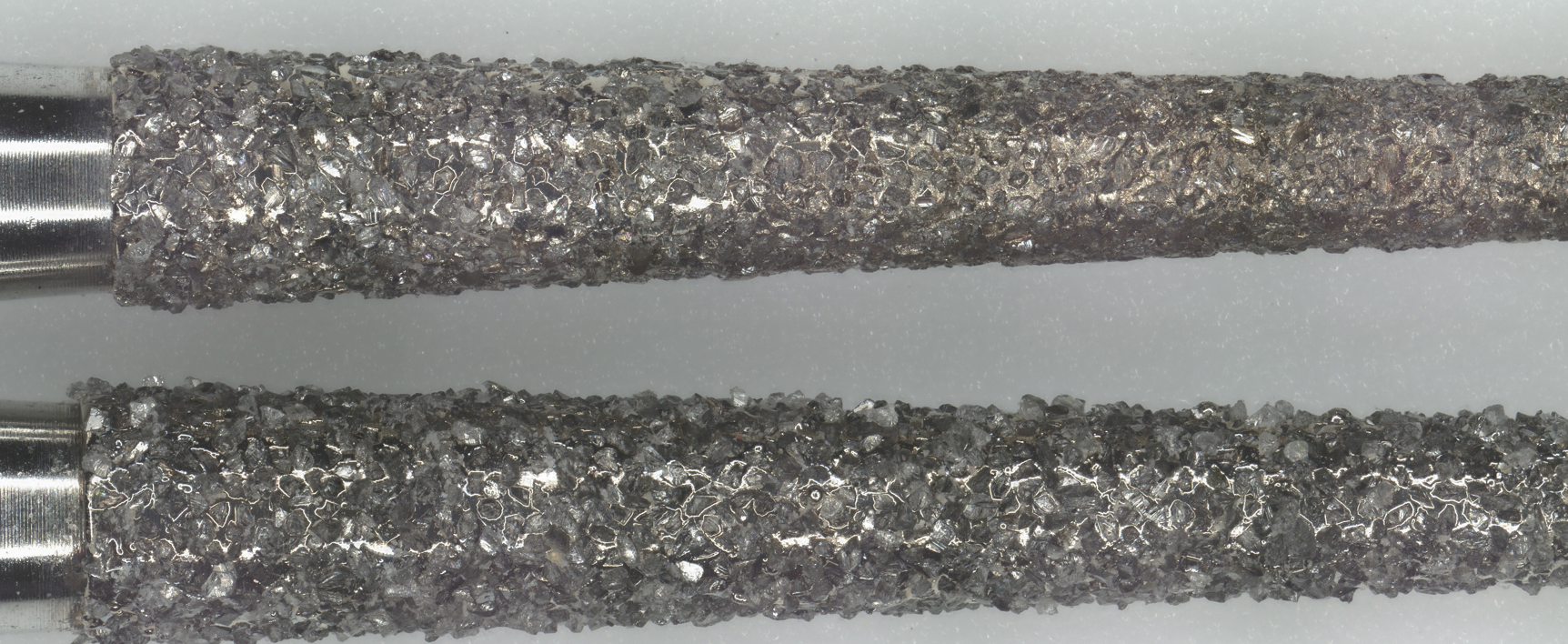

1. Diamond Coating

As we are in contact with several bur manufacturers for constant improvements we have received similar feedback from different sources, which is that the diamond coating of the bur is reduced by over 80% after 8 minutes of operation. So unless only a small cavity was treated the next tooth is cut simply by

the heat friction of a nearly blank metal shaft - Needless to say that this is neither sufficient nor pleasant for the tooth (and to the tooth-attached patient).

As now the cutting force is significantly reduced, subconsciously we are pressing harder onto the tooth to remove the same amount of material as before.

Similar to pressing the buttons on a remote control with dead batteries as hard as you can - it might give us the feeling that it has an impact, but in reality, we are just wearing out the components.

So as we tend to push harder on the tooth with the worn-out bur, we are putting a drastic amount of pressure on the bearing, which severely impacts their lifetime.

2. Damaged bur shaft

The internal handpiece mechanism is designed to hold the bur through friction, meaning there are two holding jaws that press onto the bur shaft. This created a pressure of at least 2,5kg which is sufficient to endure the high pressure from the operation.

This high pressure, however, impacts the surface condition of the bur shaft and it simply wears out over a short amount of time and the diameter of the bur shaft is reduced.

ISO 3823 requires burs to have a diameter of 1.590mm - 1.600mm.

If a handpiece is continuously used (or abused with) a bur that has a worn-out bur shaft, the holding jaws of the spindle mechanism can't fully grip the bur anymore. So under regular or higher pressure, the bur will stop while the cartridge or gear will actually

.jpg?width=422&height=237&name=worn-out%20bur%20(2).jpg)

rotate around the bur shaft. This causes the holding jaws of the spindle to be polished to the same dimension as the bur, meaning it cannot create any pressure or holding force and the bur will fall out.

Therefore ensure to consecutively check the burs on a regular basis and replace them if necessary.

You want to learn more about the construction of the holding mechanism of handpieces? Click here to read the article on the function.

All burs are being constantly checked, but you still run into issues with the holding mechanism of your handpiece?

A polished spindle can also be the result of improper spindle cleaning. To check if the required process is correctly lined with your process ensure to check out the maintenance guide.

_Druckdaten_2022.png?height=120&name=2020x500_cm_ADX22_(Blende)_Druckdaten_2022.png)