As already described in the article on the construction of high-speed handpieces, the cartridge is the heart that enables us to drill with such high force. This precision component's tremendous velocity (~480.000 rpm) is essential to provide the amount of power while not endangering durability.

You are looking for something specific? Use the guide below to find what you are looking for:

- Bearings

- Spindle - How is the bur held securely?

- Impeller

- O-rings

What are the most important components?

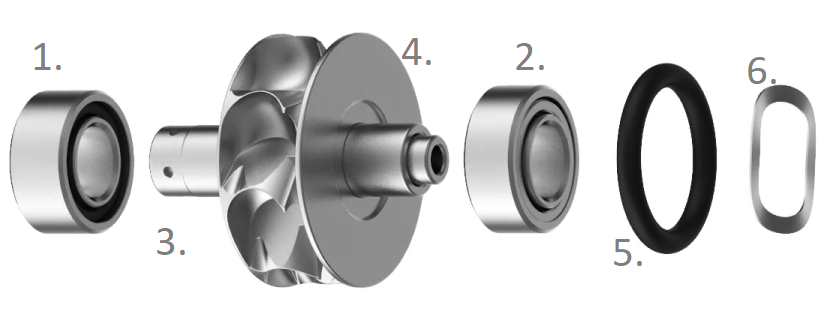

The most relevant parts of the cartridge are the bearings (1. & 2.), spindle (3.) with the internal holding mechanism and impeller (4.). Most cartridges are also equipped with the accessory components o-rings (5.) & wave spring washers (6.).

The most relevant parts of the cartridge are the bearings (1. & 2.), spindle (3.) with the internal holding mechanism and impeller (4.). Most cartridges are also equipped with the accessory components o-rings (5.) & wave spring washers (6.).

1. & 2. Bearings

The bearings are the components that actually allow the cartridge to spin. They are equipped with ceramic balls, which distribute the pressure during the operation and are held by a cage that keeps them in place as shown in the image on the right. To allow a smooth operation there is always a front and rear bearing equipped on each cartridge, whereas MK-dent uses a specific type of bearing, that prevents debris from entering.

3. Spindle system

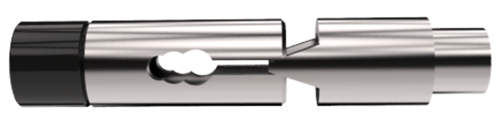

The spindle system is the component, where the bur is inserted and held in position during the operation. To successfully seat the bur, it will be inserted with the diamond coating facing outwards and then the push button of the handpiece is pushed, which opens the brackets of the collet. Beneath the cylindric or tube-shaped housing the system looks like this:

As the push button of the handpiece is pressed, the triangle-shaped pusher bends open the collet shown in the middle. The collet is now pushed opened to about 1.605mm to ensure the bur with its maximum dimension of 1.600mm can be inserted without friction.

Once the push button will be released the collet will try to go back to its natural shape (~1.550mm), which is impossible as the bur is now inserted, causing the required holding force on it.

The lowest holding force when you pull on the bur should be at least 2.5 kg | 5 lbs., as otherwise, the bur could escape from the collet during operation.

Therefore always pull on the bur after you inserted it into the handpiece

Of course, the bur can only be held with a tight grip if it is in adequate shape. To learn more about the dependency of the spindle system on the used burs click here.

4. Impeller

The impeller is practically the windmill that turns the compressed air energy (pneumatic energy) into rotational force (kinetic energy). Through air-flow measurement and computer simulations, it is the big achievement of our development team that MK-dent handpieces are among the most powerful in the market. This comes from the optimized air channe

l that makes the conversion from pneumatic to kinetic energy as efficient as possible.

5. O-rings

As insignificant as they seem the o-rings fulfill a very important role as they ensure that the bearings are seated and held in position properly. If they would be missing, the outside shell of the bearing would be held by the metal housing alone allowing the outside shell to rotate as well - which needs to be prevented at all times! If the outside shell would start to rotate, it would cause a high amount of vibration which damages the bearings significantly.

Therefore 100% of o-rings are actually measured and tested in the MK-dent factory to ensure they have the proper size and flexibility.

6. Wave spring washers

To eliminate all possible vibrations from the bearings during the operation metal springs called wave spring washer is inserted. Depending on the models they are being used for

Cartridge Balancing

At MK-dent all components are manufactured with the highest tolerances, to ensure optimal performance. In order to align the components with each other it is an absolute necessity to balance the assembled cartridge to eliminate all vibrations during the operation. This is due to the fact that the vibration is severely impacting the lifetime of the bearing so it needs to be avoided at all times.

What's important to know about balancing?

1. Sub-assembly/Combo balancing

Often times the balancing process is executed only with partially assembled cartridges with the so-called sub-assembly or combo. This is only the impeller in combination with the spindle system. We found, that it is fairly impossible to accurately measure the imbalance as it is very hard to distinguish the vibration that is only coming from these parts since the bearings are not equipped. This is actually another factor that plays a significant role as the bearing also have a slight imbalance in themselves that need to be corrected so balancing without the bearing is simply not as precise as balancing the entire cartridge altogether.

Therefore MK-dent only balances with fully assembled cartridges or perfect and precise results.

2. Accurate measuring

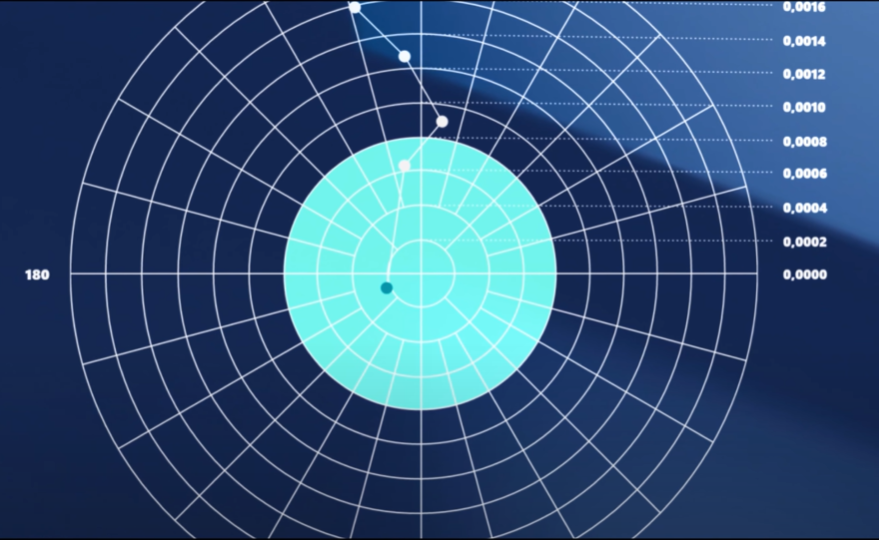

In order to eliminate the imbalance, the first thing that must be achieved is to identify at which angle it is located. This is done through a measuring tool that picks up the vibration and put it in direct relation to the rotation per minute for identification.

Usually, these measuring tools work with direct contact with the cartridge and at a speed of about 8.000 rotations per minute.

This however is not the optimum solution, as the measuring tool, which is in direct contact will experience material fatigue and will therefore be inaccurate over time, furthermore the actual operating speed of the cartridge is way higher (>300.000rpm).

Therefore MK-dent developed a measuring procedure, which operates at the actual speed of the designated cartridge while measuring contactless, eliminating any material fatigue.

3. Balancing process

Different from other industries, where weight is added to the component, in dental we only have the option to remove material, meaning that the actual imbalance is removed to the complete cartridge. As the standard operation, after measuring, a person with a drill removes the imbalance by hand as they drill a tiny hole into the shovel of the impeller, where the imbalance is located.

This poses a problem that MK-dent managed to eliminate, which is the dependency on the person to be (almost impossibly) accurate with their hand and the limitation of achieving the perfect balance.

At the MK-dent factory, we join forces, as the process is fully automated meaning the machine removes the imbalance through a laser process while an experienced team member constantly monitors the process. This way we are highly efficient and effective at the same time, achieving unmatched results.

_Druckdaten_2022.png?height=120&name=2020x500_cm_ADX22_(Blende)_Druckdaten_2022.png)