Highspeed handpieces have been one of the utmost important tools in dentistry ever since their invention in the 1960s. Since then the construction itself has not changed too much, but several tremendous developments such as air-flow measurements and automated balancing process ensure that you can work as precisely and as efficiently as ever at speeds up to 480.000 rotations per minute.

What are the most important components?

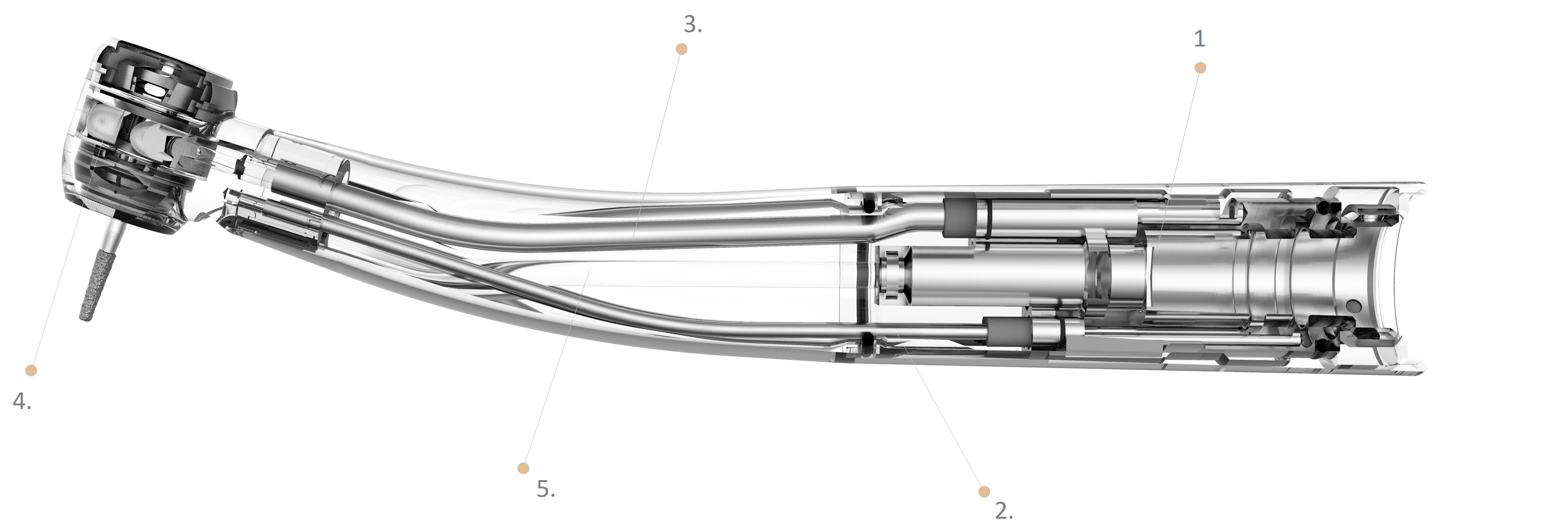

Next to the outside housing, there are 5 key components:

1. Adapter or tubing connection

On the bottom of the handpiece, the air and water are taken in and to be correctly distributed into the different channels such as air and water pipe (2.) and the drive air tube (3.). In order to operate the handpiece it is important to set the correct pressures in the dental chair for the spray water, spray air and of course the drive air.

2. Spray air and spray water pipes

From the inner adapter, the water for the spray is picked up and transported to the head of the handpiece. The same goes for the pressurized air which will then be mixed together to form a cooling mist that ensures proper cooling of the bur and tooth during the operation.

It is important to know that the pipes are always sealed by silicone o-rings that prevent leakages. If you are experiencing water leakages in the handpiece make sure to click here to check out the possible reasons.

Learn more about setting the correct pressure for your spray.

3. Drive air tubing

As highspeed handpieces are air driven, meaning the compressed air from your compressor, which is pushed through the dental chair needs to be guided to the head where the cartridge (4.) is located. So basically this tubing does the same as it's spray colleagues, it only slightly bigger and directed to a slightly different location.

Learn more about setting the correct pressure for your drive air.

4. Cartridge / Turbine / Rotor

There are several names for it but they all mean the same thing - the heart of the handpiece. This essential part is set together from 2 bearings, the impeller which creates the rotation, and the spindle where the bur is inserted. All this put together creates a magnificent piece of assembly to provide a high-power output for precise drilling.

Interested in the precision details of the cartridge? Click here to learn more.

5. Glassrod

In case you own a handpiece that enlightens the patient's mouth, it is most likely equipped with a glass rod that picks up the light from either an LED or halogen bulb and transports it to the head of the handpiece.

And how does it work?

Since all highspeed handpieces are driven by compressed air (pneumatic energy), this is exactly what we need. So at first, we need to ensure the drive air pressure is set correctly.

The compressed air is then transported through the drive air tube (3.) into the head compartment where it is directed at the impeller of the cartridge. Similar to a windmill, the drive air pushes the impeller resulting in the rotation of the cartridge. So basically we are 'only' converting compressed air (pneumatic energy) into rotational force (kinetic energy), which allows us to drill.

The compressed air is then transported through the drive air tube (3.) into the head compartment where it is directed at the impeller of the cartridge. Similar to a windmill, the drive air pushes the impeller resulting in the rotation of the cartridge. So basically we are 'only' converting compressed air (pneumatic energy) into rotational force (kinetic energy), which allows us to drill.

Of course, there are several differences in the design and construction among all manufacturers, but through modern airflow measurements and simulations, we are able to provide you not only the most powerful handpiece at 2.8 bar drive air pressure with 28W with our Power Editions but also the quietest handpieces in each class starting at below 55dB(A) in our Prime Line.

_Druckdaten_2022.png?height=120&name=2020x500_cm_ADX22_(Blende)_Druckdaten_2022.png)