As mentioned in the cleaning chapters in the maintenance (Click here to open the Manual cleaning process & automated cleaning process), leaving chemicals in the handpieces after the cleaning process actually causes contrary to what we intend - they are not clean, but congested.

RECAP:

Cleaning your equipment is an essential but often overlooked process causing early fatigue in different components. Why is cleaning so important and isn't it enough to simply oil and sterilize it?

Either cleaning your instruments through a thermal disinfector or through the manual process ensures that (visible) debris is removed which is relevant medically and mechanically. Through the cleaning process, the bacterial count can be reduced up to 1/1000 in comparison to the initial count according to recent studies. So to prevent cross-contamination among patients and health staff. Kindly note that though it might not be required by law in your country (German laws require it according to the standards of the RKI) it is required according to our instructions for use.

Secondly cleaning your instruments will drastically reduce the repairs as debris within the handpieces is broadly removed from bearings, gear sets, and all other relevant components. This debris is a mixture of internal and external matter such as old lubrication and grease, small metal parts resulting from friction in the bearings and gears, as well as saliva and blood forming a polishing paste over time that harms bearings, gears, o-rings and technically everything that come in contact with it.

As beneficial and essential as the cleaning process is, it leaves the handpieces and their vital components completely dry and exposed to external factors. If aggressive chemicals are left on these components, they will surely impact the structure of the material causing early fatigue of the products.

So how do we prevent this from happening?

- Ensure to flush the products with demineralized water and confirm that they are completely dry.

- Always lubricate the instruments according to the instructions for use.

Only highest grade materials such as surgical stainless steel are used in the production of the products. However highly aggressive chemicals can still cause surface corrosion if they are not properly removed.

Curious about what happens when this is not done right? Look no further:

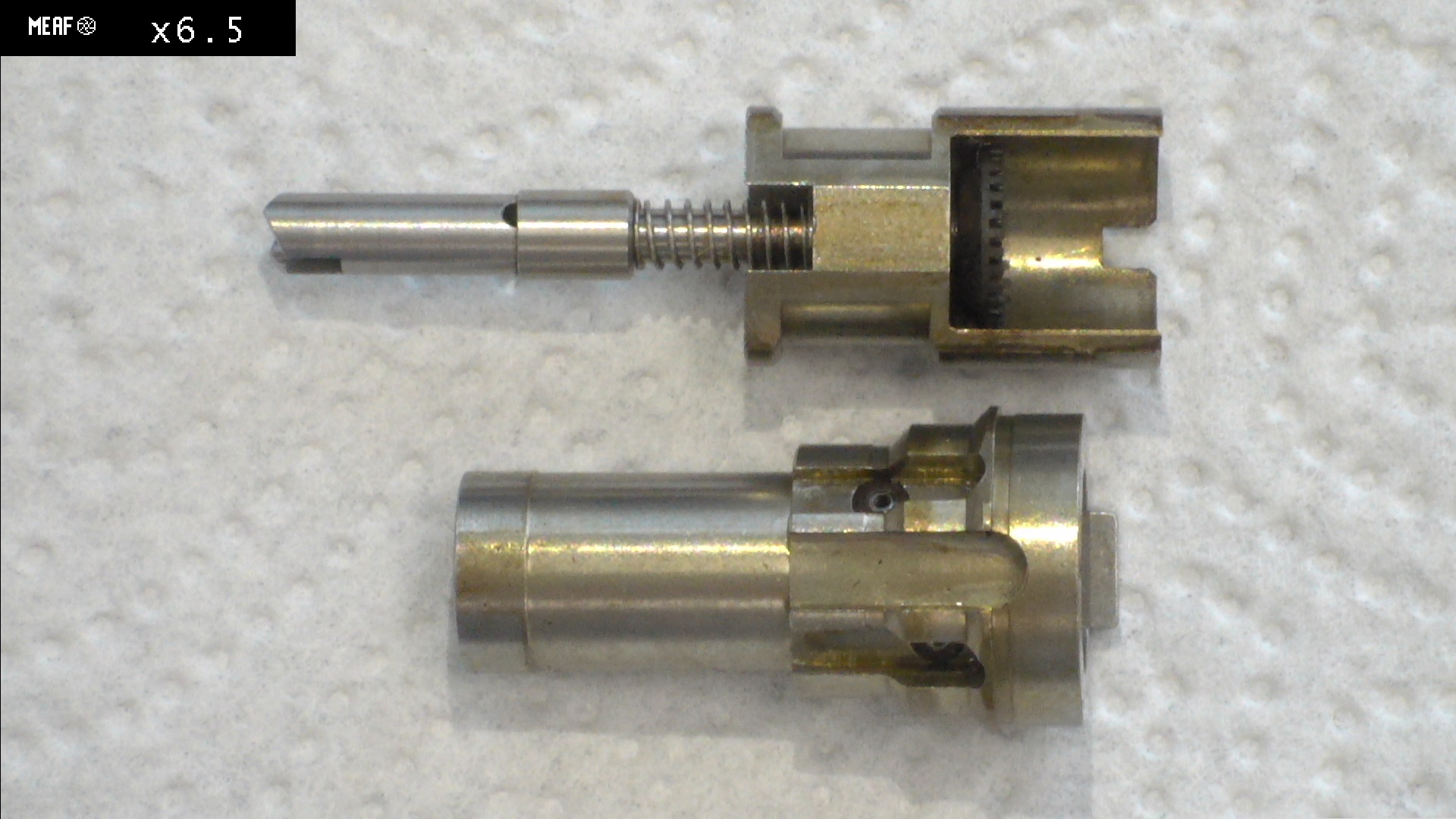

- Cleaning fluid was left inside as the thermal disinfector was not properly maintained/validated

- The contra-angle head has not been removed for some time, causing the cleaning liquid to remain between the head and contra-angle. through the sterilization, the liquid turned dark over time causing stalling of the gears and bearing and corrosion on the housing.

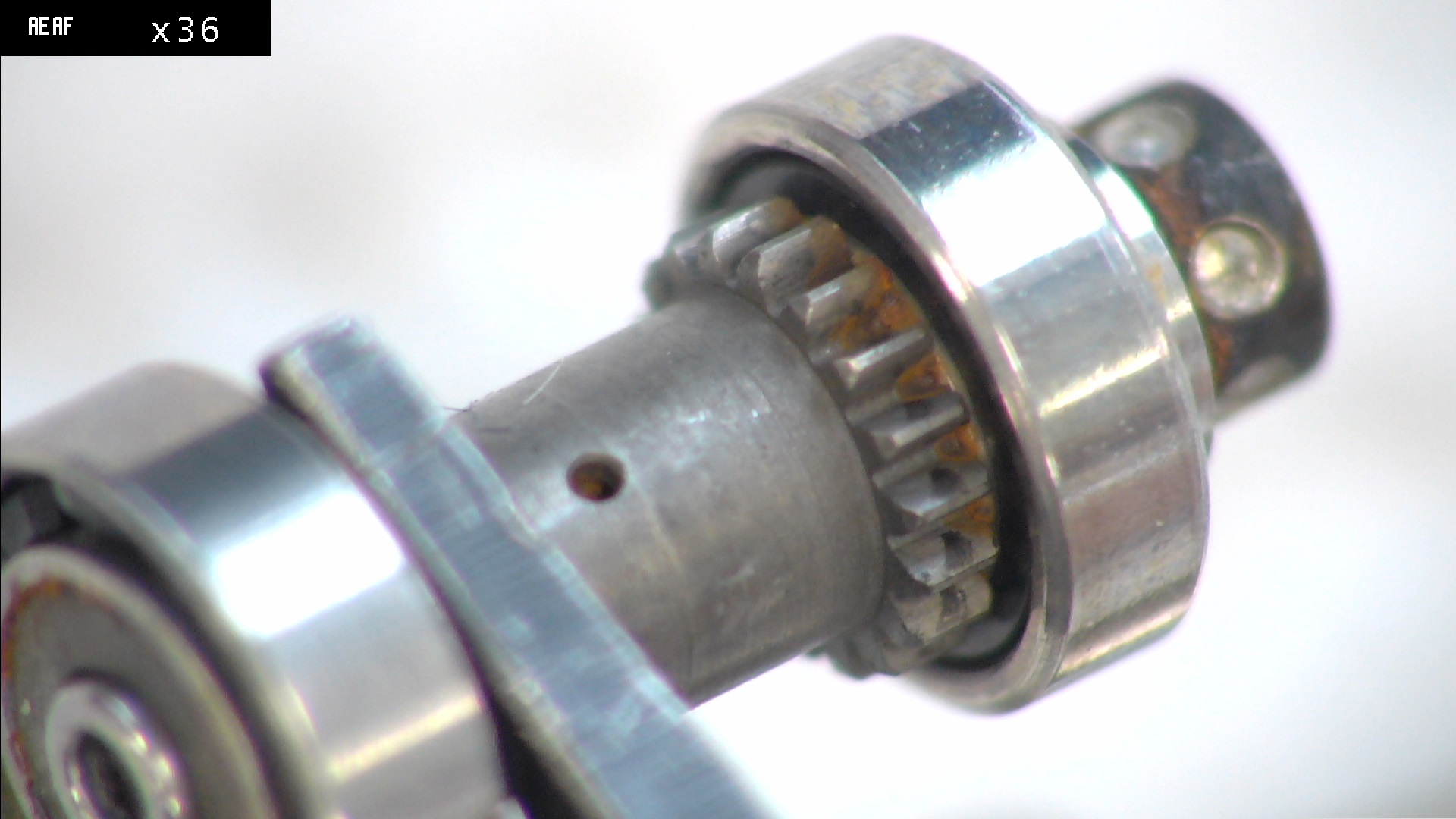

- The drying cycle was not properly executed causing cleaning and disinfection fluid to stick to the gear set of this 1:5 head gear set.

- Another 1:5 head gear with the same issue

- Original KAVO 8000B with cleaning fluid remaining in the headgear. Similar to MK-dent, other manufacturers also use high-quality materials for their manufacturing, but aggressive chemicals will still find a way to harm the performance. The product was sent to MK-dent for repair.

Original T1 Control from the same practice as the above-mentioned turbine.

- Contra-angle with fluids inside that haven't been removed for a long time.

*Disclaimer: All images shown were returned for repair at the MK-dent or a partner workshop. None of these products failed due to material or manufacturing-related reasons and only improper maintenance is responsible for the defects in the product.

_Druckdaten_2022.png?height=120&name=2020x500_cm_ADX22_(Blende)_Druckdaten_2022.png)